MENENE Hardening Induction?

Menene Induction Hardening?

Ƙarƙashin shigar da induction hanya ce ta kashewa wacce ke amfani da ƙa'idar shigar da wutar lantarki don sanya aikin aikin yanke layukan filin maganadisu a madadin filin maganadisu kuma ya haifar da halin yanzu a saman sassan ƙarfe. Dangane da tasirin fata na alternating current, saman ɓangaren ɓangaren mai zafi yana da sauri mai zafi a cikin nau'i na eddy current sannan shigar da quenching da sauri.

bayan induction dumama yana gama aikin dumama da kashewa, ƙarfin sassa na ƙarfe yana da tsayi, ainihin yana kula da filastik mai kyau da tauri, yana nuna ƙarancin ƙima, don haka tasirin tauri, ƙarfin gajiya, da juriya suna haɓaka sosai. Saboda da ɗan gajeren lokacin dumama, da surface hadawan abu da iskar shaka, da kuma decarburization na sassa kasa, idan aka kwatanta da sauran zafi jiyya, da sassa ƙin yarda kudi ne sosai low. Hakanan zabar madaidaicin induction dumama na'urar tana taka muhimmiyar rawa a fagen jiyya mai zafi na shigar da ƙarfe.

Me yasa ake amfani da tsarin tauraruwar induction?

Induction quenching wani tsari ne wanda ake samar da igiyoyin ruwa a cikin aikin karfe ta hanyar shigar da wutar lantarki kuma aikin yana zafi. Idan aka kwatanta da fasahar dumama ƙarfe na gama gari, fasahar quenching induction tana da fa'idodi masu zuwa:

1. A karfe workpiece surface taurin ne high. Taurin saman kayan aikin da aka taurare ta babban da matsakaicin mitar induction dumama shine 2 ~ 3 HRC sama da na gama gari. Ƙarfin tasirin sa na ƙarfe, ƙarfin gajiya, da juriya yana inganta sosai. Za'a iya tsawaita rayuwar sabis na kayan aikin ƙarfe da yawa ta hanyar quenching induction.

2. Kayan aikin karfe ba shine dumama ba, don haka tare da hardening induction, aikin gabaɗayan nakasawa ƙanƙane;

3. The karfe workpiece dumama lokaci ne takaice, da surface hadawan abu da iskar shaka decarburization adadin ne m;

4. Dumama tushen aiki a cikin karfe workpiece surface, dumama gudun da kuma yadda ya dace ne high;

5. Tsarin kayan aikin induction ya fi ƙanƙanta fiye da kayan aikin dumama ƙarafa na gama gari, mai sauƙin aiki.

6. Induction hardening na'ura yana gane injina da sarrafa zafin zafi ta atomatik, yana adana farashin aiki.

7. Hakanan za'a iya amfani da fasahar tauraruwar induction a cikin tauraruwar sama a cikin shigar dumama da maganin zafin sinadarai.

Yadda za a zabi tsarin shigar da ya dace?

Tsarin hardening induction yana da hanyoyin dumama da yawa kuma duk suna da kayan aikin dumama masu dacewa.

1. Hanyar ƙarfafa dumama shigar lokaci ɗaya:

Dumamar shigar da lokaci ɗaya ko dumama shigar da ita lokaci ɗaya shine mafi yawan hanyar tauraruwar shigar shigar. Lokacin da wannan hanyar ta yi amfani da bututu masu rectangular guda biyu kewaye da farfajiyar aikin don dumama jujjuyawar, yawanci ana kiranta Single Shot.

Fa'idar wannan hanyar dumama shigar da ita ita ce kammala duk aikin aikin dumama sararin samaniya a lokaci guda. Sabili da haka, aikinsa yana da sauƙi, yawan aiki yana da girma, ya dace da dumama yanki na workpiece bai yi girma ba. Domin dumama da musamman babban yanki workpiece, rungumi da daya-lokaci dumama hanya, yana bukatar babba iko da high zuba jari kudin.

Misalai na yau da kullun na hardening induction dumama na lokaci ɗaya sune ƙanana da matsakaicin modules gears, sandunan harsashi na CVJ, titin tseren ciki, ƙafafun masu ɗaukar hoto, ƙafafun tallafi, fil ɗin bazara, masu jan wuta, ƙarshen bawul, bawul rocker arcs, da sauransu.

2. Ana duba hanyar tauraruwar shigar induction:

Lokacin da yanki mai dumama aiki yana da girma, ƙarfin wutar lantarki na induction yana ƙarami, ana amfani da wannan hanyar sau da yawa. A wannan lokacin, yankin dumama da aka ƙididdige S yana nufin yankin da ke cikin zoben ƙaddamarwa. Saboda haka, wannan iko yawa, da induction dumama ikon da ake buƙata ƙananan ne, gasa induction hardening inji Farashin saka hannun jari yayi ƙasa da ƙasa, ya dace da ƙaramin ƙarar ƙarar ƙarar ƙarfin samarwa, misalan misalan su ne babban sandar fistan mai girman diamita, katakon katako, yi, bututun mai, sandar tsotsa, dogo, jirgin ƙasa jagorar kayan aikin injin da sauransu.

3. Hanyar kashe dumama ƙaramin sashi na lokaci ɗaya

Misalai na yau da kullun sune camshafts induction hardening, duk lokacin da zazzage kyamarori ɗaya ko fiye, bayan gama wannan lokacin induction quenching, dumama wani ɓangaren cam, gears suna taurare haƙori ta haƙori kuma ana iya haɗa su cikin wannan rukunin.

4. Hanyar quenching subsection induction

Misalai na yau da kullun sune shafukan rockers ko madaidaicin magudanar gudu induction hardening, inda ake duba sassa da yawa na igiya don kashewa, faɗin quenching na iya bambanta, kuma ana iya haɗa haƙori ta hanyar duban haƙori quenching cikin wannan rukunin.

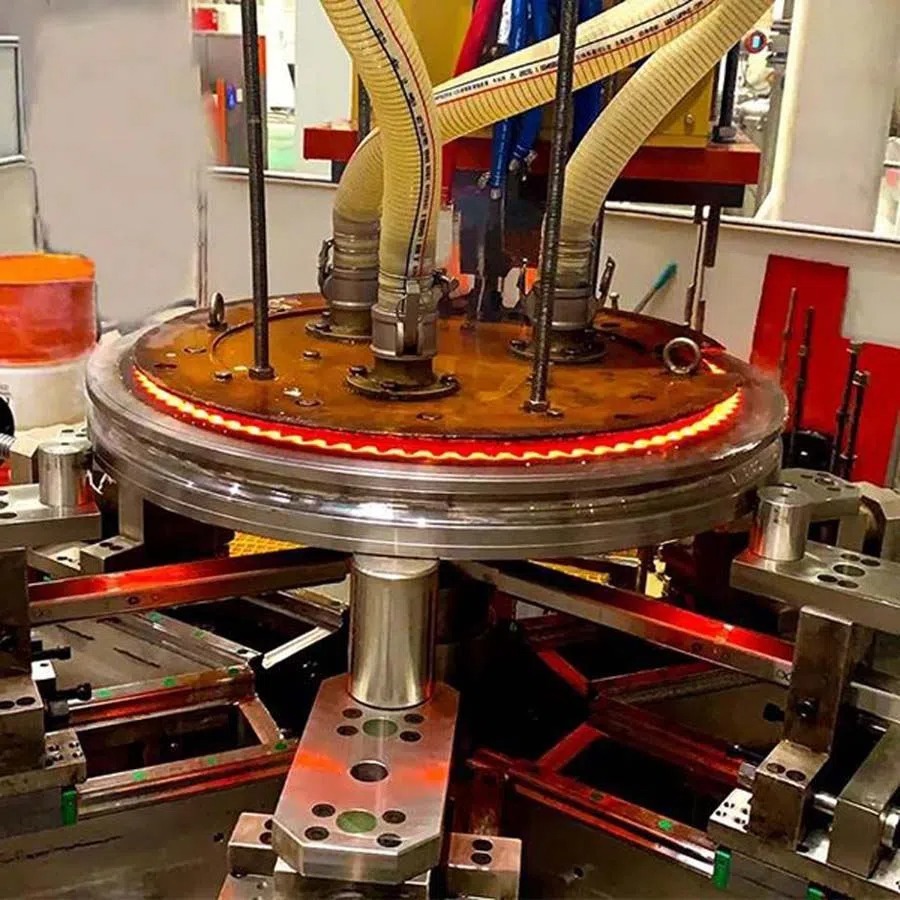

5. Induction dumama da quenching a cikin ruwa

Induction hardening quenching a cikin ruwa, yana nufin da muryar shigarwa da workpiece dumama surface an nutsar da shi a cikin shigar da quenching ruwa, mai tsanani, saboda dumama surface ikon yawa kasancewa girma fiye da kewaye quench ruwa sanyaya kudi. Saboda haka, saman yana zafi da sauri. Lokacin da inductor aka kashe, saman workpiece yana taurare saboda zafi sha na workpiece core da kuma sanyaya na quenching ruwa.

Wannan hanyar gabaɗaya ta dace da aikin ƙarfe na ƙarfe wanda ke buƙatar ƙimar sanyaya ƙasa mai mahimmanci. Lokacin da aka sanya kayan aikin a cikin iska kuma aka kashe induction coil, zafin saman yana ɗaukar tsakiyar aikin. Lokacin da adadin sanyaya na saman zafi ya fi girma mai mahimmancin sanyaya, aikin aikin yana taurare, wanda yayi kama da quenching a cikin ruwa.

Wadanne abubuwa ne ke tattare da tsarin hardening na induction?

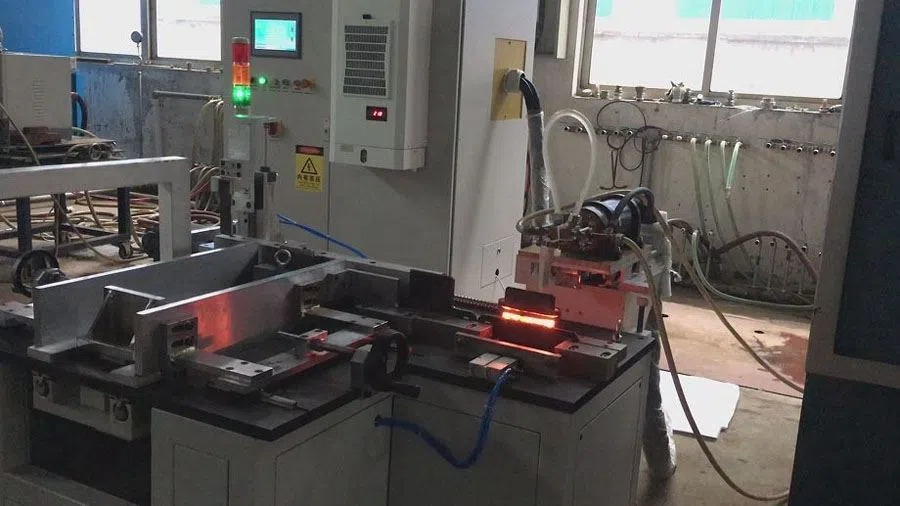

Abun da ke ciki na cikakke Injin quenching inji gabaɗaya ya haɗa da induction dumama samar da wutar lantarki, CNC induction hardening inji kayan aiki, induction hardening nada, da karin sanyaya tsarin wurare dabam dabam na ruwa da quenching ruwa wurare dabam dabam tsarin.

Masana'antun kayan aikin induction na zamani, babban ɓangaren ikon aiwatar da cikakken tsarin kayan aikin induction hardening kayan aiki da aikin maɓalli, mai amfani daga tsari don rage tsarin samarwa, kuma an kauce masa saboda sashin samar da kayayyaki da yawa a cikin aiwatar da lalata bai jitu ba, da kuma doguwar rashin lafiya kamar lokaci. Samar da cikakken kayan aiki da ayyukan maɓalli ya zama hanyar gasa ga masu kera kayan aiki.

Gabaɗaya, A matsayin ɗaya daga cikin manyan masana'antun induction hardening tsarin masana'anta a kasar Sin, mun taimaka dubunnan masana'antun sarrafa zafi don nemo hanyoyin magance zafi da suka dace tuni, don tabbatar da tsarin da ya dace da tsarin induction quenching tsarin. Don Allah za ku iya ba ni damar samun zane-zanen sassa masu taurin ku, kayan aiki, tauri, da buƙatun zurfin taurara, kuma za mu iya ba ku mai alaƙar shigar da tsarin dumama shawarwarin fasaha tare da zanen magana. Godiya.

Gabatarwa Hardening Tsarin Tsarin Sashe na Aikace-aikace

1. Ƙaƙwalwar hanyar tsere ta CNC induction quenching inji tsarin

2. Tsarin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙwara

3. Cantilever gear CNC induction hardening inji tsarin

4. Ingancin wutar lantarki ta iska da kuma tsarin samar da tsarin sa

5. Daidaitaccen shaft harsashi na ciki rami induction dumama hardening tsarin

6. Babban Mill Roller Induction Hardening